The 5th generation intelligent suspended double-head ion fan

Model:KP102A

application area

Product overview

Kp102a 5th generation intelligent suspended double head ion fan is an intelligent electrostatic removal device newly developed and produced by kapar company to eliminate static electricity on the object surface.

Kp102a 5th generation intelligent suspended double head ion fan can produce a large amount of air flow with positive and negative charges, which can neutralize the charges on the object. When the object surface is negatively charged, it will attract the positive charge in the air flow. When the object surface is positively charged, it will attract the negative charge in the air flow, so as to neutralize the static electricity on the object surface and achieve the purpose of eliminating static electricity.

Kp102a 5th generation intelligent suspended double head ion fan is provided with wind power by a small fan. The wind power can be adjusted in the touch button or remote control. The transmitting needle brush has automatic cleaning function, automatically remembers automatic cleaning every 8 hours, avoids manual cleaning, and can customize the cleaning time. It has the function of high-voltage fault wind alarm and alarm light prompt, which is audible, Visual double intuition to understand whether the equipment works normally. If the fan encounters obstacles during normal operation, the fan will automatically short circuit and stop working.

Kp102a 5th generation intelligent suspended double head ion fan is used in precision electronics, pharmaceutical manufacturing, plastics, optoelectronics and other industries.

Product features

1. Intelligent modern, exquisite appearance, fine production and novel design.

2. Automatic cleaning function of transmitting needle brush, automatic memory, no manual cleaning.

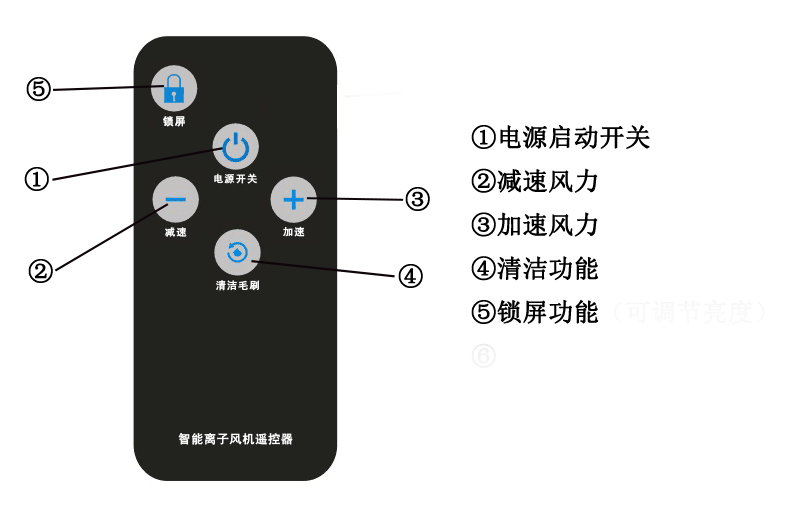

3. Remote control: touch the dual control power supply to start and adjust the wind force.

4. It has the functions of high-voltage fault wind chime alarm and alarm light prompt, and can understand whether the equipment is normal by hearing and vision

Work.

5. The remote control lock screen locks the wind speed, and the electrostatic removal of ion fan in the workshop is standardized.

6. When the fan encounters obstacles during normal operation, the fan will automatically short circuit and stop working.

7. High static removal speed, low balance voltage and high safety performance.

8. Energy saving and environmental protection, low power consumption.

Technical parameter

control panel | LED digital display | Fan speed gear (lock, foolproof) |

Auto Clean button | Automatic cleaning every 8 hours (0-8 hours can be designed by yourself) (lock, foolproof) | |

error alarm | Wind beeps / indicator light flashes red | |

Touch the button to adjust the speed | Remote control/touch dual control (lock, foolproof) | |

wind speed | Remote control/touch dual control (lock, foolproof) | |

power on | Remote control/touch dual control (lock, foolproof) | |

One key lock screen | Remote control (lock, foolproof) | |

power supply | Power supply intelligent frequency conversion AC 220V/filtering anti-interference | DC intelligent control system/fan DC12V |

Socket wiring is on the back | / | |

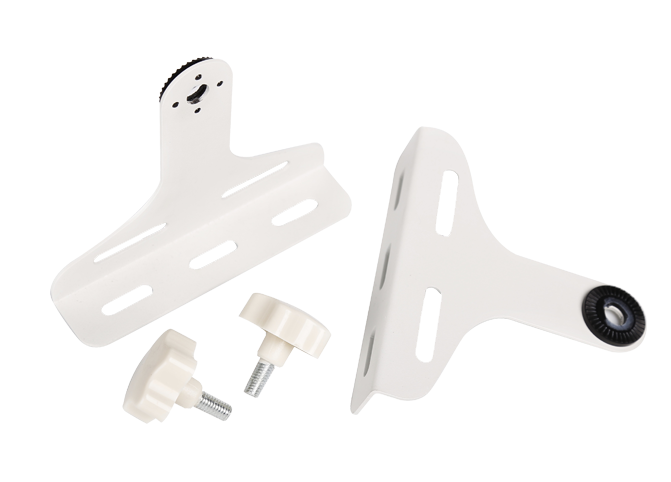

Exterior | a fixed way | The angle has a foolproof function, and special tools are required to adjust the angle |

Material | Cold rolled sheet | |

surface | electrostatic spraying | |

ribbon | able to provide | |

Front plastic windscreen | Can be disassembled freely | |

Rear plastic windscreen | Optional filter | |

case ground | No leakage (safety) | |

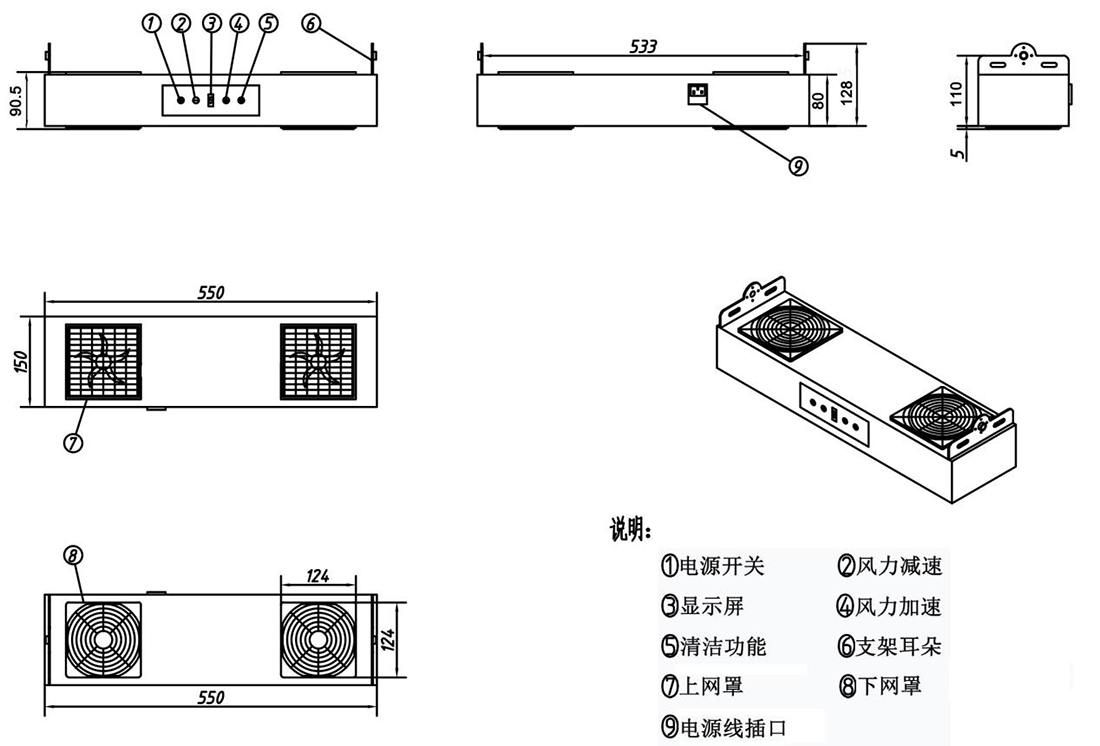

Dimensions with ears (without stand) | 550mm(L)*150mm(W)*130mm(H) | |

Electrostatic facilities | Discharge needle automatic cleaning | / |

Discharge needle material | Tungsten alloy, non-removable (lifetime > 3 years) | |

Power down time | ≤2S (300MM from the product) | |

Ion balance | ≤±|10V|(300MM from the product) | |

Connection method | Inverter AC 5.0KV | |

Anti-static effective control radius 300mm | 300MM from the product | |

fan | Fan air volume≤5.1m3/min | 300MM from the product |

power | 10W | |

working distance | 100-600mm | |

Operating temperature | 0-50℃ | |

Working humidity | 56%-65% | |

Air volume | 80-220CFM | |

noise | 45-60dB | |

net weight | About 4.5kg | |

Gross weight | About 5.2kg | |

other | One year warranty | |

Test result

Test Conditions | |||||

Humidity: ≤60% Test voltage: 1KV-100V Ambient temperature: 22℃ | |||||

distance | 300mm | 600mm | |||

Neutralization time | just | 0.8s | 1.1S | ||

burden | 0.8s | 1.2S | |||

residual voltage | just | +5v | +8v | ||

burden | -6v | -8v | |||

* The test results of the test instrument using ME268A electrostatic comprehensive tester shall prevail.

* Tested according to IEC-61340-5-1 A·6.

* Tested data may vary due to changes in ambient temperature and humidity.

Remote control function

Overall dimension

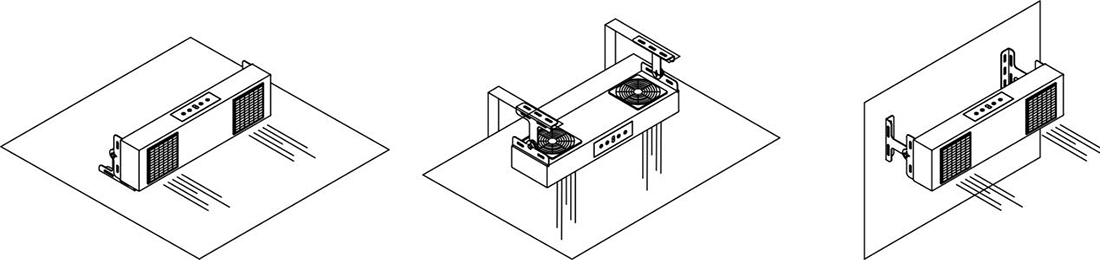

Installation mode