The 4.5th generation mechanical and intelligent ion air rod

Model:KP502A

application area

Product overview

The KP502A 4.5th generation mechanical and intelligent ion air bar is the latest static removal device developed and produced by Kapal to eliminate static electricity on the surface of objects.

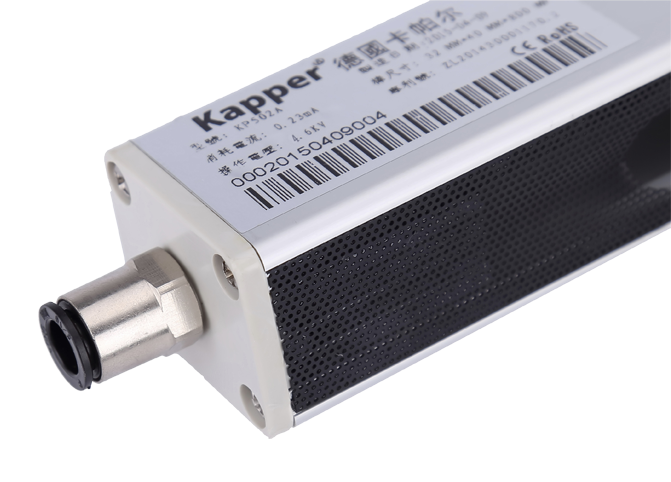

KP502A 4.5th generation mechanical and intelligent ion air bar is a kind of static removal device commonly used to eliminate electrostatic adsorption dust. It needs to be equipped with compressed air and KP401A 4.5th generation mechanical and intelligent high voltage power supply with a working voltage of 4.6KV before it can be used. The length can be customized according to customer's requirements.

KP502A 4.5th generation mechanical and intelligent ion wind rod can generate a large amount of airflow with positive and negative charges, which can neutralize the charges on objects. When the surface of the object is negatively charged, it will attract the positive charge in the airflow. When the surface of the object is positively charged, it will attract the negative charge in the airflow, so that the static electricity on the surface of the object is neutralized and eliminated. purpose of static electricity.

KP502A 4.5th generation mechanical and intelligent ion air rods are widely used in electronics, printing, packaging, coating production lines and other industries.

Product features

1. Exquisite appearance, fine production and novel design.

2. Sturdy and durable, strong wind, suitable for various harsh working environments.

3. The neutralization of static electricity is rapid, the dust removal effect is good, and the balance voltage is low.

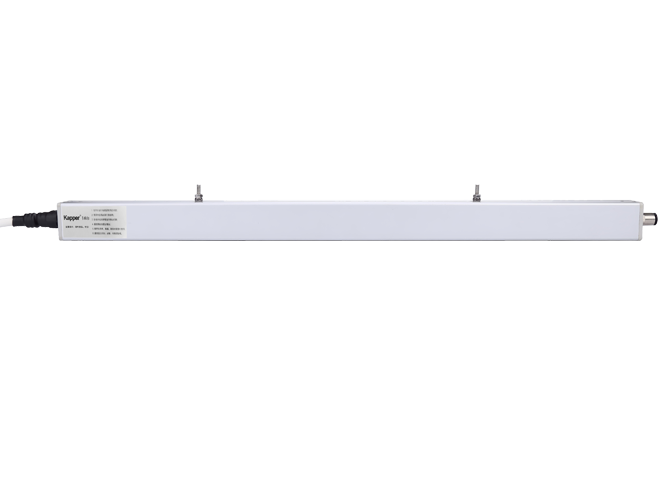

4. The rod body has a special bar-shaped notch, and the installation bolts are movable and convenient.

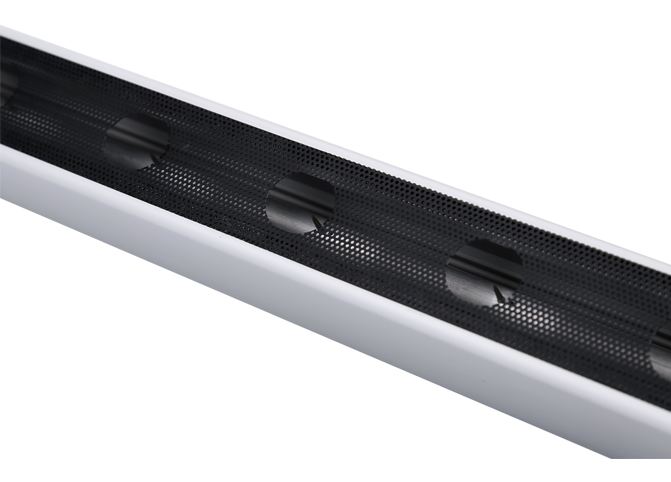

5. The mesh can effectively prevent the finger from directly contacting the high-voltage ion needle and cause the risk of high-voltage electric shock.

6. The wind rod has a good grounding protection function.

Technical parameter

Use voltage | 220V/50Hz or 110V/60Hz |

The output voltage | AC 4.6KV |

working distance | 100-300mm |

Operating temperature | 0℃-50℃ |

Working humidity | <70% |

net weight | About 0.9kg/600mm (including 3M high-voltage wires) |

use medium | clean compressed air |

Air supply connector | Ф8mm |

Rod length | 200-3000MM(Customized according to customer requirements) |

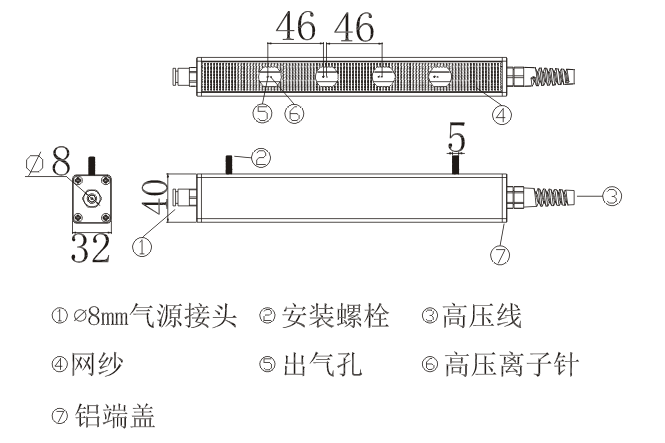

cross-sectional area | 32mm(W)*40mm(H)* X(any length)mm |

Rod material | Aluminum |

High voltage wire length | 3M |

compressed air pressure | 40-70psi |

Test result

Test Conditions | |||

Humidity: ≤60% Test voltage: 1KV-100V Ambient temperature: 22℃ | |||

distance | 300mm | 600mm | |

Neutralization time | just | 0.8s | 1s |

burden | 0.7s | 1.2s | |

residual voltage | just | ≤|±90V| | |

burden | |||

* The test results of the test instrument using ME268A electrostatic comprehensive tester shall prevail.

* Tested according to IEC-61340-5-1 A·6.

* Tested data may vary due to changes in ambient temperature and humidity.

Overall dimension

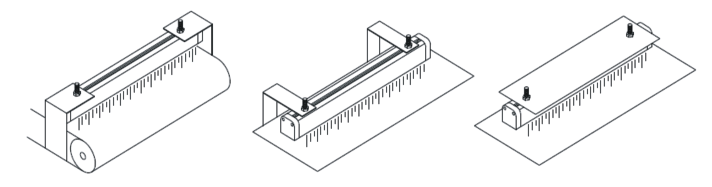

Installation mode